"I incorporated the idea of failure explicitly in all the courses I teach. I emphasize that virtually every engineering calculation is ultimately a failure calculation, because without a failure criterion against which to measure the calculated result, it is a meaningless number. "

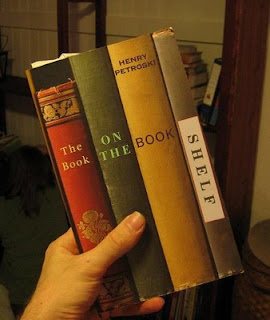

~ Henry Petroski, Duke Professor of Engineering & History

I've never met Dr. Petroski, but for his writings alone he is one of my favorite engineers. (Not my favorite, that spot is reserved in perpetuity, but maybe a close second.) Not least of all because he wrote two wonderful books on the history and design of two of my favorite things in the world: bookshelves and pencils.

He also teaches his Duke engineering students from the writings of Vitruvius and Galileo to underline for them the fact that failure is nothing new, and is something to be embraced and learned from.

All of which leads us from the heights of engineering to my humbling and bumbling attempts at thimbling.

It has occurred to me repeatedly the past couple weeks that it has been a long time since my high school "metal arts" class. The class was woefully misnamed because it was almost wholly devoted to preparing students for careers in the sheet metal and HVAC industries.

That I nevertheless managed to convince the teacher to let me make armor and two swords instead for class credit is almost beside the point. Nerds probably shouldn't be allowed to take metal shop. We're nothing but trouble. (The look on the face of the assistant principal when he caught me walking a broadsword to my locker was priceless, though nothing compared to when he found out I'd only brought it to school to be graded... but that's another story.)

Suffice to say, that the word "dapping" was never uttered in that metal shop and if I'd asked how to make a thimble, I'm not sure I'd have received an answer. So I wasn't as prepared for some of the silliness that has cropped up between me and the sewing notions as I'd hoped.

The middle American high school just does not adequately prepare you for life in the real world of 1580. We should do something about that.

Here's where we stand on this project:

The middle American high school just does not adequately prepare you for life in the real world of 1580. We should do something about that.

Here's where we stand on this project:

I've reached a standstill on the thimble making project. Now that I've solved my metal problems, I can adequately troubleshoot things enough to see that my tools are inadequate to the task. Even with a metal face attached, the hardwood dapping block is still not making the grade.

I need a better setup.

One of my failings in planning for this project was acknowledging that, pinners notwithstanding, most of the craftspeople in the 16th century didn't make their own tools. I don't know why I thought making my own dapping tools would be either easy or necessary. I won't be making my own anvil for the blacksmithing section of the show any more than I plan to make my own hammers.

My wife talked to some of her friends at work out in the metal shop and they agreed that the tools were the most likely hook on which to hang blame for my failures. Unfortunately, none of the commercially-available dapping pins and blocks look to be quite right for creating the shape of a period thimble.

So I'm sort of stuck for the moment on this project.

Inspired by a comment Maggie Secara made on the Facebook page, I made this topless thimble (wolf whistle) out of a bit of copper pipe I had lying around. It's a valid stopgap moves things along to the forming and dimpling stages. It's a bit of a cheat, admittedly, but it is the type of thimble I prefer when sewing since I tend to push the needle with the side of my finger instead of the tip.

I need a better setup.

One of my failings in planning for this project was acknowledging that, pinners notwithstanding, most of the craftspeople in the 16th century didn't make their own tools. I don't know why I thought making my own dapping tools would be either easy or necessary. I won't be making my own anvil for the blacksmithing section of the show any more than I plan to make my own hammers.

My wife talked to some of her friends at work out in the metal shop and they agreed that the tools were the most likely hook on which to hang blame for my failures. Unfortunately, none of the commercially-available dapping pins and blocks look to be quite right for creating the shape of a period thimble.

So I'm sort of stuck for the moment on this project.

Inspired by a comment Maggie Secara made on the Facebook page, I made this topless thimble (wolf whistle) out of a bit of copper pipe I had lying around. It's a valid stopgap moves things along to the forming and dimpling stages. It's a bit of a cheat, admittedly, but it is the type of thimble I prefer when sewing since I tend to push the needle with the side of my finger instead of the tip.

It isn't pretty, but it is effective. In the meantime, I'm exploring having a proper dapping block made if I can't find one that will work on the commercial market. (Any leads on that front would be most welcome.)

As I mentioned in the last post, I've also begun working on the Worshipful Company of Coopers and since the weather has turned, will have a parallel project that will keep me inside until it turns again.

More to come, as always!

~Scott

You wouldn't happen to have a TechShop nearby, would you? (http://www.techshop.ws/) If you do, you might be able to pay or bribe a local member to CNC mill you a thimble dapping block, or failing that you might be able to take a class and make one yourself.

ReplyDelete